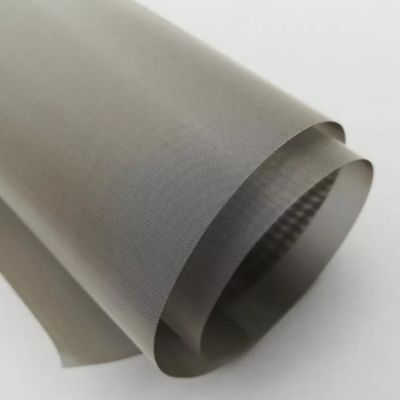

Fe Cr Al Mesh/Screen, Fireplace Screen Material FeCrAl Woven Wire Mesh/Metal Net/Burner Screen

Product Details:

| Place of Origin: | China |

| Brand Name: | Jiechang |

| Model Number: | Fe Cr Al Mesh/Screen |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 square meter |

|---|---|

| Packaging Details: | Seal up, with plastic inside and wooden case or carton outside; |

| Payment Terms: | L/C,T/T,Western Union, paypal, D/A, D/P, MoneyGram |

|

Detail Information |

|||

| Material: | Material | Application: | FeCrAl Alloy Wire Mesh Widely Used In Drying And Heating Equipment In Metallurgy, Colliery, Dyeing, Food Factory, Hospital, High Density Board Factory And Cardboard. |

|---|---|---|---|

| Wire Diameter: | 0.05-2.03mm | Mesh: | 1-200 Mesh |

Product Description

Fe Cr Al Mesh/Screen have high resistance, low temperature coefficient of electric resistance, high operating temperature, and good corrosion resistance under high temperature, especially under the atmosphere containing and/or sulfides. Fe Cr Al Mesh/Screen has less hot strength than nickel alloys but much higher melting point and lower price. After being heated the alloy's plasticity becomes bad, easy brittleness, not to be easy to weld. However, If can be reasonably used, they also be a kind of ideal electric heating material. To ensure the quality of these very fine wires, the best materials and strict quality controll system were applied.

| Type | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Chemical composition | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | opportune | opportune | opportune | opportune | opportune | opportune | opportune | |

| Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

| Maximal Temperature (oC) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resistivity 20oC (10-6ohm*m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Density(g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Thermal conductivity (KJ/m*h*oC) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| Extend strength (a*10-6/oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

|

Melting point ( oC)

|

1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Tensile strength(N/mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Percentage elongation (%)) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Section shrink rate(%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| curve strength(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| hardness (H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Microstructure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Magnetism | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

FeCrAl woven wire mesh is made of iron-chromium-aluminum alloy containing small amount of reactive elements such as yttrium and zirconium. It has outstanding heating resistance, oxidation resistance performance. It is mainly used in the industry electric furnace, household appliances. It is an ideal material for heating and drying.

Material Type:1Cr13AL4,1Cr12AL4,0Cr21AL6,0Cr23AL5,0Cr25AL5,0Cr21AL6Nb,0Cr27AL7Mo2

Mesh Counts:1-200 mesh

Wire diameter:0.05-2.03mm

Weaving type: Plain weave and twill weave

Feature: •Heating resistance.(1250-1400 degrees,usually 800-1000 degrees)

•Oxidation resistance.

•Sulfur resistance.

•Anti-carburizing.

•High surface load.

•Long lasting and durable.

•Low temperature coefficient of resistance

Usage: 1. FeCrAl alloy wire mesh widely used in drying and heating equipment in metallurgy, colliery, dyeing, food factory, hospital, high density board factory and cardboard.

2.It is an ideal heating material for Industrial electric furnace,household electrical appliance,infrared device and so on.

![]()