China Hastelloy Mesh

Product Details:

| Place of Origin: | China |

| Brand Name: | Changgu |

| Certification: | ISO 9001 |

Payment & Shipping Terms:

| Payment Terms: | L/C,T/T,Western Union, paypal |

|---|

|

Detail Information |

Product Description

|

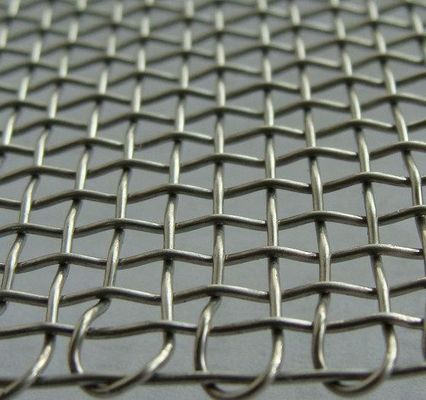

Hastelloy mesh |

Hastelloy X mesh |

|

Hastelloy B mesh |

|

|

Hastelloy C276 mesh |

|

|

Hastelloy C-22 mesh |

1.Hastelloy X mesh Description

Hastelloy X mesh is a nickel-chromium-iron-molybdenum super alloy with outstanding high temperature strength, oxidation resistance, and fabric ability. Hastelloy X mesh oxidation resistance is excellent up to 2200ºF. Hastelloy X mesh has also been found to be exceptionally resistant to stress-corrosion cracking in petrochemical applications, resistant to chloride stress-corrosion cracking, carburization, and excellent resistance to reducing or carburizing atmospheres. .

2. Hastelloy B mesh Description

Hastelloy B mesh is capable of withstanding high temperature, stress, severe corrosion and erosion prone environment. The predominant ingredient used in our Hastelloy B mesh is high grade metal Nickel. The other grades that we offer our clients are Hastelloy C and Hastelloy X mesh follows are main introductions of Hastelloy X mesh.

Uses of Hastelloy B

Hastelloy B mesh was found extensively usage in nuclear and chemical reactors, pipes and valves in diverse chemical industries.

3. Hastelloy C276 mesh Description

Nickel-chromium-molybdenum wrought alloy that is considered the most versatile corrosion resistant alloy available. Alloy C-276 also has excellent resistance to pitting, stress-corrosion cracking and oxidizing atmospheres up to 1900? (1037.8?). Alloy C-276 has exceptional resistance to a wide variety of chemical environments.

Uses of Hastelloy C276 mesh

This alloy is resistant to the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process applications in an as welded condition.

4. Hastelloy C-22 mesh Description

Hastelloy C22 mesh is a versatile austenitic nickel-chromium-molybdenum-tungsten alloy with enhanced resistance to pitting, crevice corrosion and stress corrosion cracking.

Resistance Nature of Hastelloy C-22 mesh for:

1. Oxidizing media while the molybdenum and tungsten content give good resistance to reducing media.

2. Oxidizing aqueous media including wet chlorine and mixtures containing nitric acid or oxidizing acids with chlorine ions.

3.Oxidizing acid chlorides, wet chlorine, formic and acetic acids, ferric and cupric chlorides, sea water, brine and many mixed or contaminated chemical solutions, both organic and inorganic.

4.Resistance to environments where reducing and oxidizing conditions are encountered in process streams.

5. This nickel alloy resists the formation of grain-boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process applications in the as-welded condition.